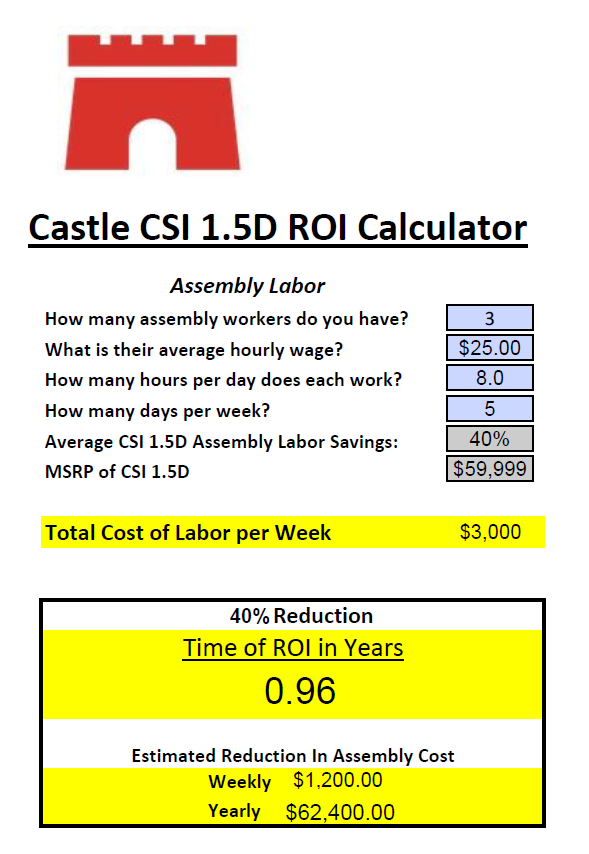

Product Description

CSI 1.5D Pocket Cutter/Screw Inserter Machine

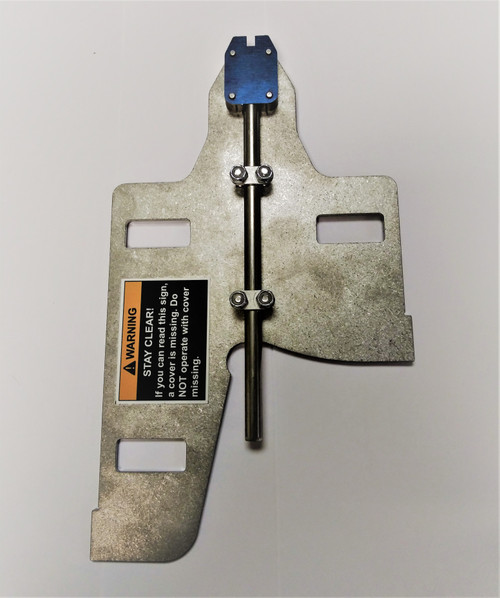

The CSI-1.5D Pocket Cutter/Screw Inserter Machine cuts Castle’s 6 degree low-angle pocket, drills a pilot hole, and inserts a screw - all in 1.5 seconds. The CSI-1.5D produces stackable parts in faster production times, reduces waste, and eliminates non-value-added labor in high-capacity production joinery. The CSI will quickly become your assembly team’s go-to tool—no more fumbling for screws, and it protects their hands from those pesky little cuts caused by handling fasteners! And, in customer time tests, CSI reduces assembly time by up to 40%.

The CSI-1.5D Pocket Cutter/Screw Inserter has a super heavy-duty, robust build with customizable work decks and flip stops for efficient and accurate material alignment. It is designed for continuous production, requiring simple, routine maintenance so that down time is minimized. The CSI-1.5D is used with composites, panel and hard/soft wood.

Optional Air Tables, SideShift Auto Positioner, Hi-Lo Plate, and Offset Work Decks.

Features and Benefits include:

- Pocket cutter and screw inserter in one step - patented technology reduces assembly time by 40%

- Cuts the 6 degree, Castle low-angle pocket, for strong, stable, tight, and superior joints

- Cuts pockets and inserts screws in 1.5 seconds, eliminating non-value-adding labor

- Designed for high-capacity, continuous production joinery for maximum throughput of stackable parts

- Low-angle pockets minimize the need for clamping during assembly

- Footswitch with automated operation is simple and easy to use

- CSI-1.5D comes ready to work for fast integration

- Customizable work decks and flip stops for efficient and accurate material alignment

- Air table option - perfect for panel and large part production

- Hi-Lo Plate option - for easily handling dado material

- SideShift Double Pocket Autopositioner option - automatically positions the stock and creates two, low angle, 6° pockets with screws

- Manufactured in the USA

U.S. Patent #6,877,536 | Canadian Patent #2,456,044

Which Bits Are Right For Me?

Details

Castle’s CSI-1.5D Pocket Cutter/Screw Inserter has a super heavy-duty, robust build. It is designed for continuous production, requiring simple, routine maintenance so that down time is minimized.

Detailed Benefits & Design Features:

- 1.5 second, single operation pocket cutting and screw insertion

- Inserted Screws are below flush – parts can be stacked without marring

- Works with 1-1/4” or 1-1/2” pocket screws Shop Castle screws

- “Pocket Detect” sensing prevents loaded-pocket cutting errors

- Easy access to carriages for quick tooling changes

- Adjustable router feed rate optimizes quality and cycle time for various materials

- Includes premium, solid carbide router bit and drill bit

- Also Available:

- Optional air table specifically designed for the CSI 1.5D, for panel/large part processing; runs on 230V 3-phase or 460V 3-phase and extends the work surface on either side to 59"

- Customizable work decks and work stops for efficient and accurate material alignment

- Hi-Lo Plate - for easily handling dado material

- SideShift Double Pocket Autopositioner automatically positions the stock and creates two low angle, 6° pockets with screws

Key Components*:

- Siemens LOGO! PLC controls

- LCD status display with cycle counter

- Variable frequency drive

- Teknomotor .44HP 220/380V 18000 RPM drill spindle

- Teknomotor 2.7 HP 220V OR 460V 18000 RPM router spindle

- Castle screw delivery system w/vibratory feeder bowl level sensor

- Heavy duty, Parker Viking Xtreme Series valves w/manual override

Technical Specifications:

- Electrical: 230V 3-phase or 460V 3-phase

- Air: 85 psi with minimum 3/8” ID supply line

- Dust collection: 4” dust port

- REQ CFM: 350 CFM with 4” dust collection

- Footprint: 35” x 33” (35” x 63” including Screw Feeder)

- Working Height: 36”

- Machine Height: 72”

- Worktop Area: 33” x 35”

- Shipping Weight: 1085 LBS.

- For best results with the CSI, modified pan head screws are recommended.

- Manufactured in the USA

*Actual brands and models are dependent on 3rd party suppliers.

Product Videos

Videos Hide Videos Show Videos

-

CSI 1.5D Screw Delivery System (SDS)

Castle’s CSI-1.5D Pocket Cutter/Screw Inserter saves time, red...

-

How to operate the CSI Air Table

In this video, Glyn from Castle will walk you through how to o...

-

Castle CSI 1.5 D at Custom Craft Cabinets

Max Durney takes you on a quick tour of Custom Craft Cabinets ...

-

Castle ACPI Visit

Castle Inc. CSI 1.5 D Screw pocket machine. Cuts a Pocket, dri...

-

Amazing CSI 1.5D Operator at Masterwrap

Castle CSI 1.5 D on the Job at Masterwrap. To learn more abo...

-

SideShift Auto Positioner. Double pockets, with screws… in under 4 seconds!

Get two perfectly aligned, low angle, 6 degree pockets with sc...

Custom Field

Product Reviews

2 Reviews Hide Reviews Show Reviews

-

A real game changer!

It’s been a real game-changer for our team. We’re all surprised at how fast it works, with easy tooling changes and low overall maintenance. The support that Castle provides has been beyond our expectations.

-

Well worth the investment!

We shave off 4-5 seconds per pocket without having to dig around for screws. Since we do 2,000 to 3,000 pockets per week, the CSI’s labor savings are huge. We’re a small, family-owned business with about 15-20 employees, and the increase in our production, above-and-beyond customer service, and easy operation has also been great for us.