Pocket Joinery

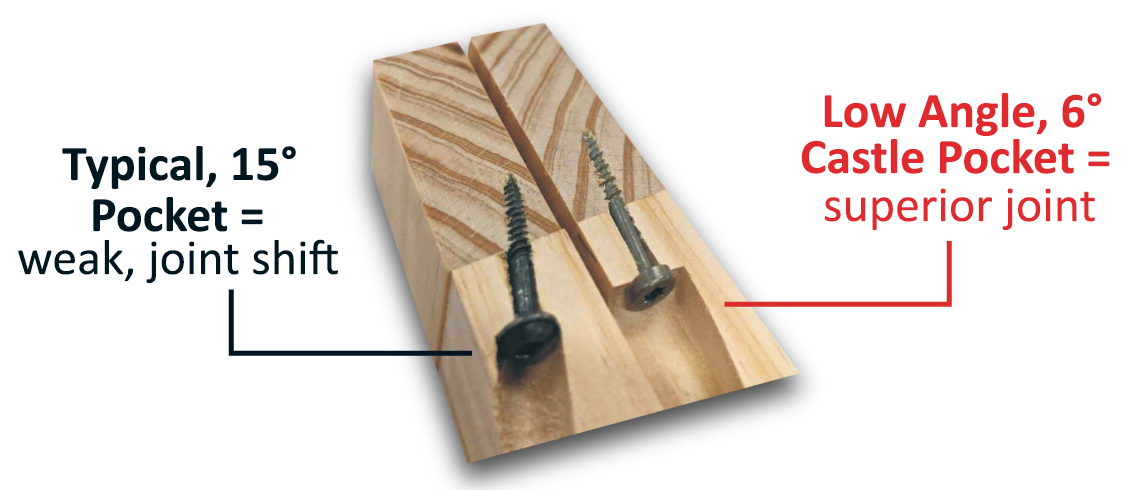

Low-Angle, 6° Pockets

Castle founder Max Durney invented the first pocket cutter capable of creating low-angle, 6° pockets. Since Castle was the very first manufacturer to design and build these machines, the Castle brand became synonymous with “Low-Angle Pocket” which is why we, and many others, refer to “The Castle Pocket” to this day.

The Castle Pocket allows a screw to go into the part you’re joining/fastening at an extremely low, 6° angle. Why does this matter? When the screw enters at a low angle, not only is the joint stronger and more stable, joint shift is minimized, if not eliminated altogether. No joint shift means less finish work!

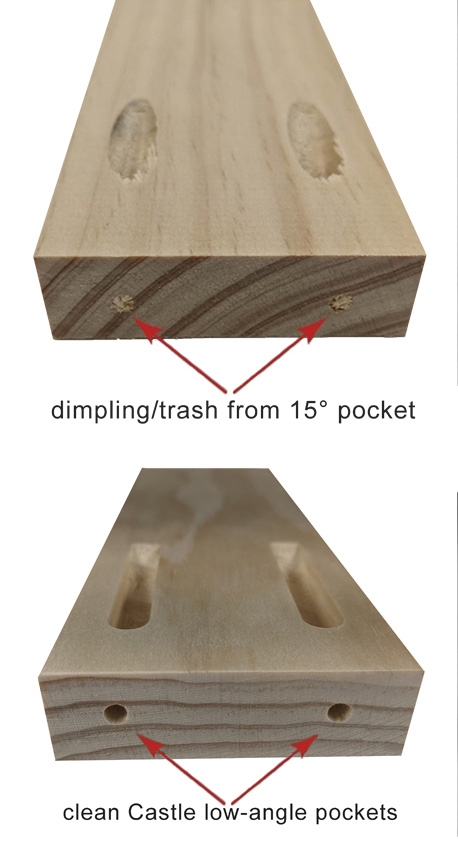

Our machines also cut pockets with a router, making crisp and clean pockets even in composite materials like plywood. This is important because you can cut clean pockets on composites without destroying the outer veneers like you would with the 2-step drill method.

No Clamping, Gluing, or Sanding

Assembly times are 60% to 70% faster than traditional joinery methods; shooting a series of pockets and assembling the parts immediately is a better way than milling, gluing, clamping, waiting hours for the glue to cure and then sanding.

We encourage woodworkers to try the “no-clamp” method with our pockets. With low-angle Castle pockets, the chance of any shifting overpowering clamps is minimal. This is a known problem with typical drilled pockets.

Softer woods are typically a little easier than hardwoods when using the "no clamp" method. And of course, straight-grained woods without knots make this process even easier. In woods like oak, the combination of hard and soft grains can contribute to a misaligned screw start by the screw tip diverting to the soft grain. To combat this, you can either run the screw spin backwards briefly or use low pressure at the start. In both cases, it will dig a starting hole more centered with the pilot hole. While the "no clamp" method does take a bit of practice, we recommend clamps if the user is more comfortable with them or if it is a critical joint that absolutely must not shift. In all cases, the Castle low-angle pocket greatly reduces angular screw pressure to make accurate assembly easier and faster.

Most Castle screw pockets are strong enough that glue is not necessary. One area we recommend glue is when 2 mating surfaces are visual and finish will be applied. Glue will bond the joint so that the 2 surfaces can’t expand/contract over time at different rates. Otherwise, you will eventually see a slight “lip” as the wood moves. Some woodworkers may choose to glue all joints.

A broad range of professionals and amateurs utilize Castle machines to leverage their production efficiencies. Commonly used applications with Castle machines include joining face frames on cabinets, frameless cabinets, drawer boxes, toe kicks, hospitality furniture, and store fixtures. Castle customers rave about their ability to consistently produce effective joinery solutions in record time with various applications in a variety of materials. Woodworkers and manufacturers continue to use Castle machines in new and innovative ways such as with piano construction, mobile home manufacturing, and crown molding.